In Pole Position

Switch from manual production to automation, and from 2D to 3D engineering

Usemco has taken a giant leap forward and boosted its competitiveness big time in recent years. Based in Tomah, in the U.S. state of Wisconsin, this leading manufacturer of pump stations is now one of the big players in its sector. This is thanks to the systematic transformation of its plant and equipment manufacturing operations via the consultative guidance and solutions from EPLAN and Rittal Automation Systems, including the switch from manual production to automation, and from 2D to 3D engineering.

Around ten years ago, Sean Rezin was despairingly googling “CNC milling machines for panel building” and “switchgear manufacturing”. “I thought there had to be CNC milling machines out there and, consequently, a way of automating enclosure machining,” recalls the young Executive Vice President of Usemco. In-house investigations relating to the production process revealed significant weak points.

“It was frustrating having to fabricate panels manually and laboriously drill holes in enclosures by hand. We were giving our staff work they actually didn’t want to do at all,” he openly admits. “We wanted to be competitive, but our panel building and switchgear manufacturing business was on its knees,” he continues. When searching online, Rezin came across an article about the Perforex drilling and milling machine. He immediately got in touch with the author, Van Miller, who is currently a value chain consultant at Rittal and EPLAN in the USA. This set everything in motion.

A bold move

The idea of using a Perforex to machine enclosures was initially met with scepticism by the Usemco workforce. “They thought automation was just something for mass production, not for custom projects and definitely not for batch sizes of one,” explains Rezin. However, following a thorough shopfloor assessment and ROI plan, purchasing the Perforex in 2018 proved to be an initial milestone in the further development of engineering operations. Even though the drilling and milling layouts still had to be entered directly into the Perforex software, the efficiency benefits were immediately obvious.

A complete overview

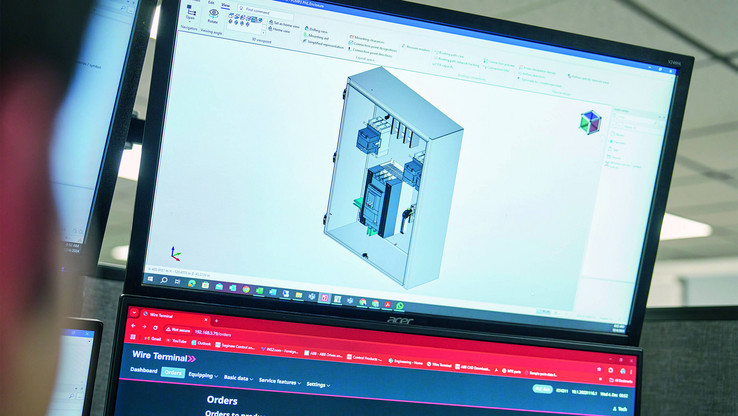

“Thanks to the Perforex, this side of our business became more successful every year – but that suddenly stopped. To become competitive, we had to invest further in the process as a whole,” says Rezin. That meant making the move into automated wire processing. “One prerequisite for this, however, was switching from 2D to 3D engineering, along with an end-to-end engineering process based on EPLAN software solutions such as EPLAN Electric P8 and Pro Panel,” he continues. That involved completely transforming the engineering and production process. Up to that point, this process had been inefficient due to the numerous manual steps involved. Enclosure layouts were still being created manually, laboriously scanned in and sent to customers in PDF format. This was the normal approach used by the rather conservative water management sector, and by many Usemco staff who had been with the company for over 40 years.

A stroke of luck for Usemco – at the age of just 24, Nikesh Chawla established 3D engineering together with his team and successfully integrated EPLAN software into production operations.

©Michael Koch/Digital Fotogroup

Young blood makes all the difference

However, the switchover called for software expertise. “We wanted to start using EPLAN and the Wire Terminal, but we didn’t have any engineers who could do that,” recalls Rezin. He had just two electrical engineering design staff back then, and they couldn’t learn how to use the new software alongside their day-to-day project work, never mind roll it out. “That meant I had to look outside the company to find suitable engineers. It wasn’t easy and we had to be creative,” says Rezin. He finally found what he was looking for at the University of Wisconsin and was able to recruit a few young engineers.

He really struck it lucky with Nikesh Chawla, who was just 24 and brand new to EPLAN but gained an in-depth understanding of the software and, after instructive guidance from EPLAN, had the necessary know-how to transform the entire process – from design and planning through to production. “Nikesh and his team integrated EPLAN into production operations, which resulted in huge efficiency gains,” enthuses Rezin. The cumbersome creation of layouts on the machine has become a thing of the past. All production tasks now come directly from the engineering section, including both enclosure machining and automated wire processing.

From 180 to 700

Partnering with EPLAN and Rittal changed the entire process – from engineering all the way through to production.“In 2015, we manufactured around 180 enclosures. Now, thanks to the Wire Terminal, we’re producing up to 700 a year,” says a delighted Rezin. The company’s sales team and customers are also benefiting. “Our sales staff now sell in a different way. It has improved the entire product portfolio,” Rezin continues. Instead of scanning in drawings, they now simply send a download link. The 3D models show customers exactly what the solution looks like. “That makes our market position much stronger, because many companies in our sector don’t use 3D engineering,” reveals Rezin.

Sean Rezin is making a real success of Usemco. The company manufactures prefabricated, enclosed pump stations for municipal water management.

©Michael Koch/Digital Fotogroup

USEMCO

Tomah, Wisconsin, USA

Founded in 1963 and headquartered in Tomah, in the U.S. state of Wisconsin, Usemco is an industry leader in engineering and manufacturing custom pump stations, water boosters, control systems, modular buildings and steel fabrication solutions. All its pumping stations are pre-assembled, factory- tested solutions that simply require electrical and piping connections.

A boost to business

Mr. Rezin, U.S. industry is booming. What challenges do you face as a plant and equipment manufacturer?

The market really is booming, especially the water management sector. Business is skyrocketing thanks to the government’s Infrastructure Investment and Jobs Act. The flipside, though, is the skills shortage. That’s no secret in the USA. Usemco operates in a rural region, so we have to compete with other companies for well-trained people.

What specific steps are you taking to find skilled workers?

We normally find engineers. If we also want to take on people who are less well qualified, we need to make our production processes much simpler – our wiring, for instance. Rittal automation technology helps us achieve that. Without it, these people would have no chance of wiring enclosures. It’s difficult finding mid-level staff with two years’ training.

How has your competitiveness changed in recent years?

Our company has been completely transformed over the past five to ten years. We used to work with 2D wiring schematics and scanned-in CAD drawings. Now, absolutely everything is digitalised. We’ve boosted our competitiveness big time and doubled our share of business.