Wire Harness

Combining Mechanical and Electrical Engineering, Making Complexity Manageable

The trend to increasing electrification is increasing the proportion of electrical components, cables and wires in many products – from construction vehicles and robots through to our home personal computers. Using professional tools and intelligent software is becoming increasingly important to maintain an overview of important factors during product design including the necessary space, the total weight and resulting costs. Additional complexity is added to product development due to frequent change requests from clients. This complexity can be made manageable for you – by using sophisticated systems that connect mechanical engineering and electrical engineering and that derive information relevant for manufacturing. This allows you to increase the quality of your products while lowering costs at the same time.

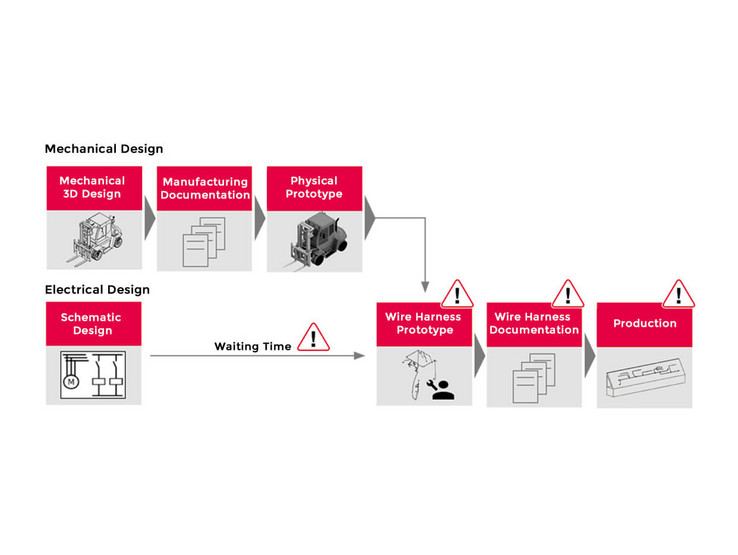

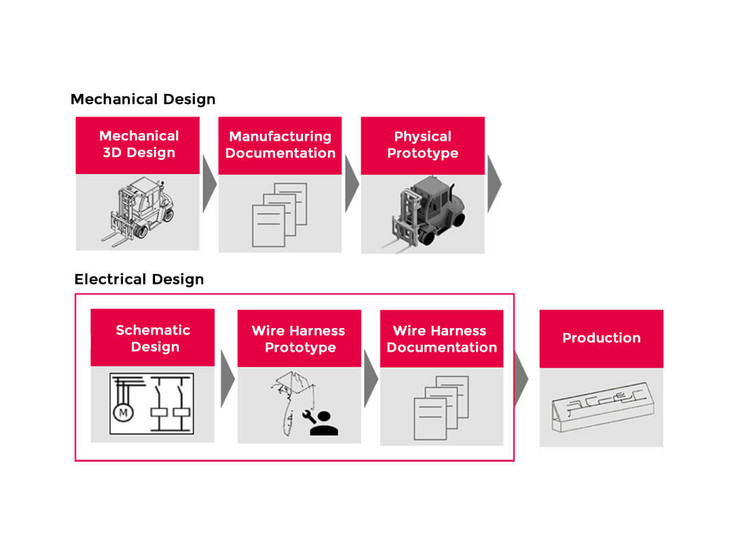

Wire Harness Development: Comparing Traditional and 3D Designs

Constructing and documenting wire harnesses can be viewed as a critical juncture at the interface between design and production. Working with a digital twin in wire harness development is worth the effort – for your company as well. This is shown, for instance, with a direct comparison to the traditional approach.

The Digital Twin and Designing Wire Harnesses

Gartner says it. Deloitte says it. EPLAN says it, too: the digital twin is becoming the driving force of industrial production in the twenty-first century. Embedded into the megatrends of Industry 4.0 and the Industrial Internet of Things, the digital twin brings manufacturing companies significant advantages across the entire product life cycle.