EI&C Engineering

Integrated Planning of Actuators/Sensors Through to PLC and DCS with EPLAN

Electrical, instrumentation and controls (EI&C) engineering combines various specialised areas in engineering. With EPLAN, you have the right engineering solution at your fingertips for every specialised field. With EPLAN Platform’s uniform database, you also keep track of interdisciplinary tasks.

Connecting Various Engineering Fields

One of the central tasks of EI&C engineering is electrical engineering. However there are various overlapping fields and connections to other technical areas that must also be considered.

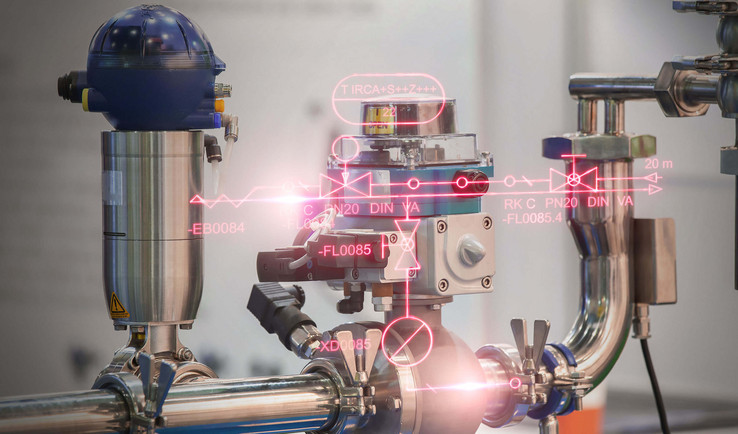

Measuring Devices for Various Values and Dimensions

Measuring technology’s purpose is to obtain information about actual objects that must be measured, for instance about a measured process or measurement section. Measuring technology deals with devices and methodologies for measuring electrical and non-electrical values, which can include electrical current or voltage, flow, mass, force, pressure, pH value, temperature and time.

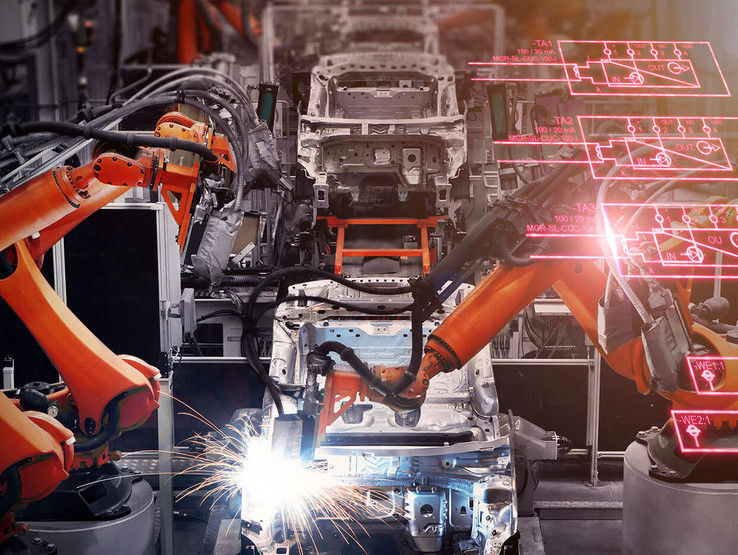

Focus on PLC as a Control Device

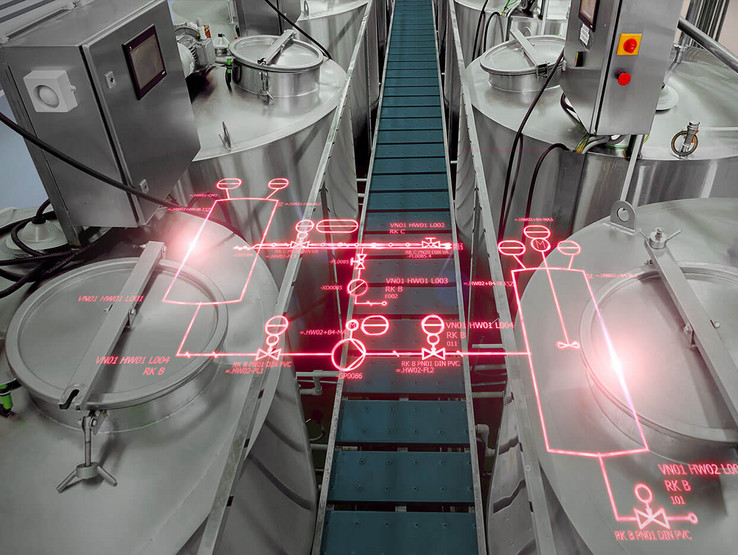

In control engineering, certain processes are implemented in a control object, for instance in a controlled process or control section. The dominant binary control technology is based on binary measurement signals, which can be generated by a threshold switch when required. In practice, decentralized control systems (DCS) or programmable logic controllers (PLCs) are the most frequently used control devices. Control technology can also be regarded as a sub-discipline of automation technology and process engineering.

Stable Processes, Structured Process Management

Control objects such as controlled processes and controlled systems ensure stable processes and structured process management in this field. These should be largely independent of disturbance variables.

Myriad Challenges for EI&C Engineering

Various overlapping specialised areas makes EI&C engineering a discipline with many different tasks and challenges. This makes standard-compliant designs and an integrated database in engineering even more important. This is where you can rely on solutions such as EPLAN Preplanning.

Tasks from Designing to System Programming

The components and connections that need to be designed vary depending on the EI&C technology field. Examples include the connections of all field devices such as sensors and actuators through to decentralised control systems (DCS) and programmable logic controllers (PLC). Junction boxes, marshalling rack enclosures and DCS control cabinets for managing and regulating control components must also be designed. This also applies to switchgear systems for power supply and controlling pumps, ventilators and heating elements. Landing measuring signals on terminal strips in the marshalling rack enclosure need to be scheduled and the power supply for the measurement device designed. You also need to determine wire lengths and program the DCS. Last but not least, supervisory control and data acquisition (SCADA) systems also need to be designed – a type of application that makes higher-level controls and data acquisition possible. Yet another important engineering task is the creation of loop diagrams for documenting the required process system.

Important Standards for Your Engineering Projects

The ISO 10628 and ISA 5.x standards are important for creating schematics. System structuring can also be carried out according to the IEC 81346 standard amongst others to enable interdisciplinary engineering. Finally, IEC 61355 regulates the type of documentation for more clarity. In addition, the PCT loop concept allows you to also orient your system designs according to NAMUR recommendations such as NA 50. The PCT system structure can be created in the Preplanning Navigator, which is where you can also create, edit and manage structural segments, PCT loops, PCT loop functions, containers and general planning objects. There are also other important standards that apply in the context of process engineering.

High-Quality Device Data

Using the EPLAN Data Portal gives you access to numerous high-quality device and component data from a constantly growing pool of manufacturers.

Efficiently Designing Loop Diagrams for Interdisciplinary Use

Creating loop diagrams in EI&C engineering is easy and fast if the following is true: terminals and terminal strips are defined and connected quickly and easily; cables are easy to route and identify and cross-references are easy to manage in the documentation. Automatic creation of the diagrams and evaluations of bills of materials should also be possible. Another important element beyond this is dealing with DCS and PLC: both the assignments and creation of overviews should work without a hitch.

Create Loop Diagram Data for Downstream Use

EPLAN Preplanning lets you capture your loop diagram data in the integrated EPLAN Platform environment. Connecting instrumentation objects using cables is also available in the software, which allows you to define which segments will be connected to one another in the preplanning phase. Connections between devices and device sources and targets can also be designed in this way.

Integrated Engineering Through to Electrical Engineering and Fluid Power Designs

External data can also be imported into EPLAN Preplanning for an iterative engineering approach. Using drag-and-drop, the data can be used for the partially automated creation of fluid power diagrams or schematics by using EPLAN Fluid and EPLAN Electric P8. You can of course also utilise the data generated in EPLAN Preplanning for your electrical engineering and fluid power designs without any media disruption.

Automatically Generate Loop Diagrams

EPLAN Engineering Configuration (EEC) give you the possibility of automatically generating loop diagrams in EPLAN Fluid and in EPLAN Electric P8. It even works using external Excel tables that you might receive from your clients as an example. This data can additionally be imported and used for generating schematics and fluid power plans.

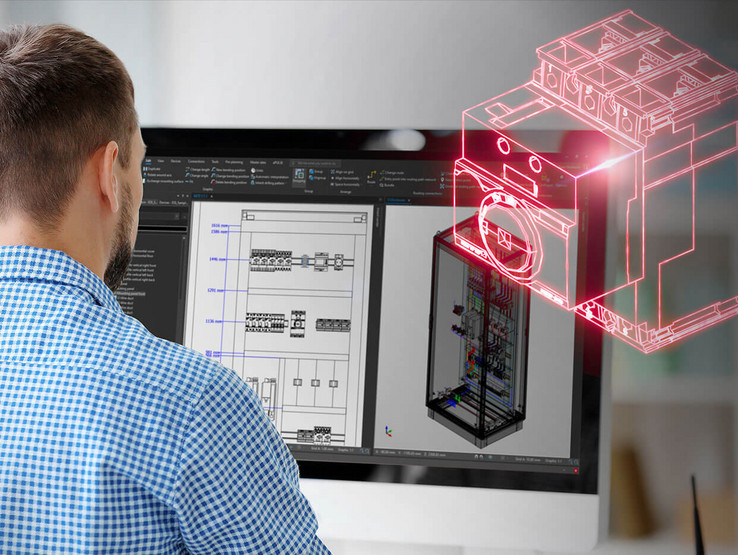

Data Transfer to 3D Engineering of Control and Switchgear Systems

You can also use all the data enriched throughout the entire engineering process to create the digital twin of your planned control and switchgear systems in EPLAN Pro Panel, which provides valuable documentation and information for manufacturing as well as for maintenance and servicing.