Service and Maintenance

Digitalised Processes – From Engineering to Production and Maintenance

Success for industrial companies is strongly related to their work in maintenance an servicing, which prevents machine and system failures and enables the best possible utilisation and availability of plant systems over their entire service life. You can also further optimise your operational processes and help ensure good budgeting of costs. As a plant operator, you face challenges every day – in engineering there are often various data formats being used and paper-based schematics. Different formats for designations and project structures make project management more difficult. And even accessing up-to-date plant system documentation isn’t always ensured. EPLAN offers you integrated solutions for digitising your processes.

EPLAN Offers Data Continuity for Service and Maintenance

Before getting started with the actual electrical engineering, already existing engineering data are collected in the preplanning phase and integrated into the data value creation. EPLAN Preplanning supports you in this. The basic electrical schematics are created in EPLAN Electric P8, where you can also save macros for re-using project data. For pneumatic systems and fluid power engineering, there’s EPLAN Fluid, while wire harnesses are designed using EPLAN Harness proD. Finally, EPLAN Pro Panel takes things to three-dimensional control cabinet designs. EPLAN eVIEW then makes all the engineering data from your EPLAN Project required for system operations available in the cloud.

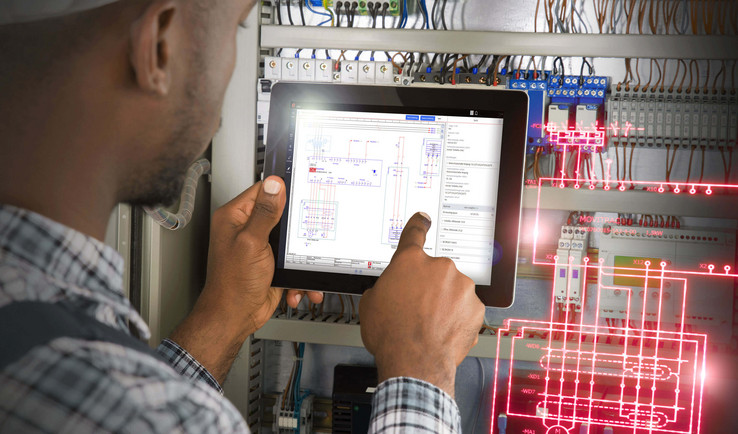

EPLAN eVIEW

With EPLAN eVIEW, you can look at project data and comment on changes – easily using a web browser no matter where you are. The software intuitively leads you through your greenlining and redlining process. It results in smoothly functioning communication between projects, specialist departments and even various companies, suppliers and service providers. The work is completely paperless, using up-to-date data from the cloud. Clearly definable access rights ensure data security.

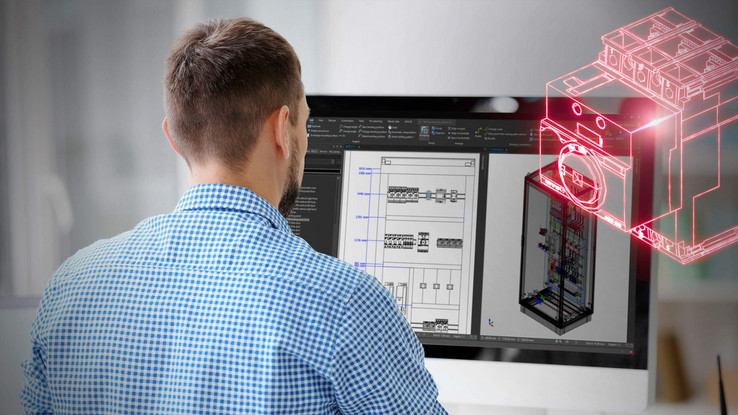

EPLAN Pro Panel

With EPLAN Pro Panel, your designs head into the third dimension. Based on data from 2D schematics, you can create a three-dimensional digital prototype of your control cabinet. Extensive information for manufacturing can be derived from the control cabinet model. At the same time, the digital twin of the control cabinet supports all maintenance and servicing activities – particularly for target/actual monitoring and fault analysis in the event of a malfunction.

Integrated Digitisation for Your Engineering Data

EPLAN provides you all the necessary data in a single software environment. Moving forward, we support your company in standardising different and usually neutral file formats such as DWG, DXF, Word and Excel documents and PDFs in one system, enabling you to comprehensively digitise your engineering planning based on logical data. This foundation provides optimal support for plant operations, plant approvals, commissioning and regular inspections. There is an incoming check of documentation right at the start of a project, and any deviations from the supplied documentation and your own database are immediately identified and recorded. The specified quality is therefore guaranteed with just one mouse click.

EPLAN in Practice

Find out how companies are using our solutions to meet current technical and economic challenges and to improve their competitiveness.